31 Jan Stainless Steels

Related to their high Chromium (Cr) content stainless steels are steels that are resistant against corrosive effects of different atmospheric conditions, various chemical aqeous, low and high temperatures and temperature variations.

According to EN 10088-1, stainless steels are defined as steels with 10,5 % min. Chromium (Cr) content.

Chromium (Cr) is the basic element that provides stainless characteristics. Standart oxidation free energy of Chromium (Cr) is lower than Iron (Fe) which provides a better selective oxiadation property. But oxides which are formed on the surface of this material is relatively more dense and deeply bounded with main material. This kind of oxide layer protects main material from any other oxidation reaction.

Nickel (Ni), provides stainless steels stable at austenitic phase even at room temperature and application area of different service conditions.

Apart of Chromium (Cr) and Nickel (Ni) some alloying elements such as Copper (Cu), Molybdenum (Mo), Titanium (Ti), Aluminum (Al) and Columbium (Nb) are effective for serving a better corrosion resistance, mechanical properties and machinability.

Stainless steels are most commonly divided into five main groups.

- Ferritic Stainless Steels

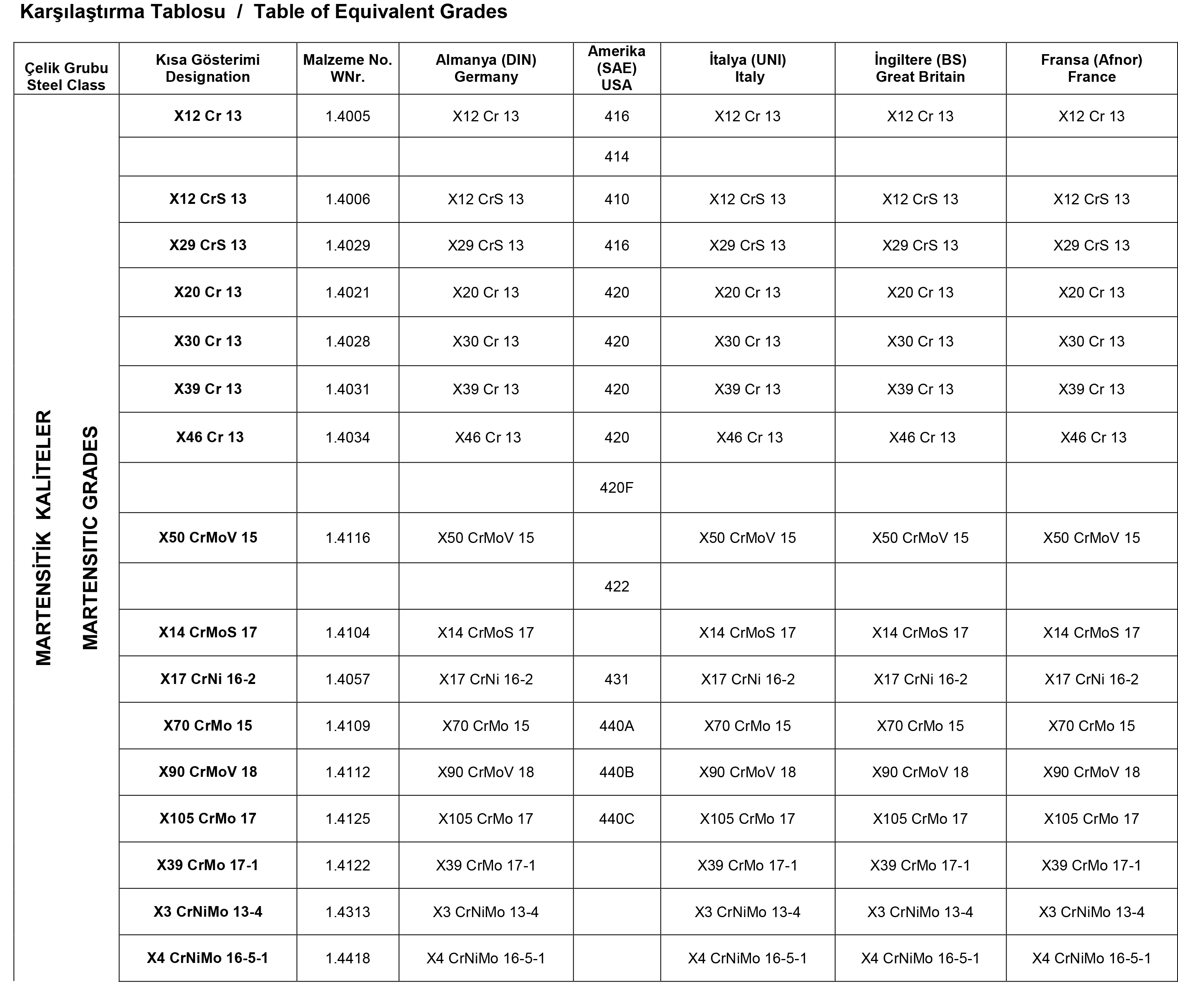

- Martensitic Stainless Steels

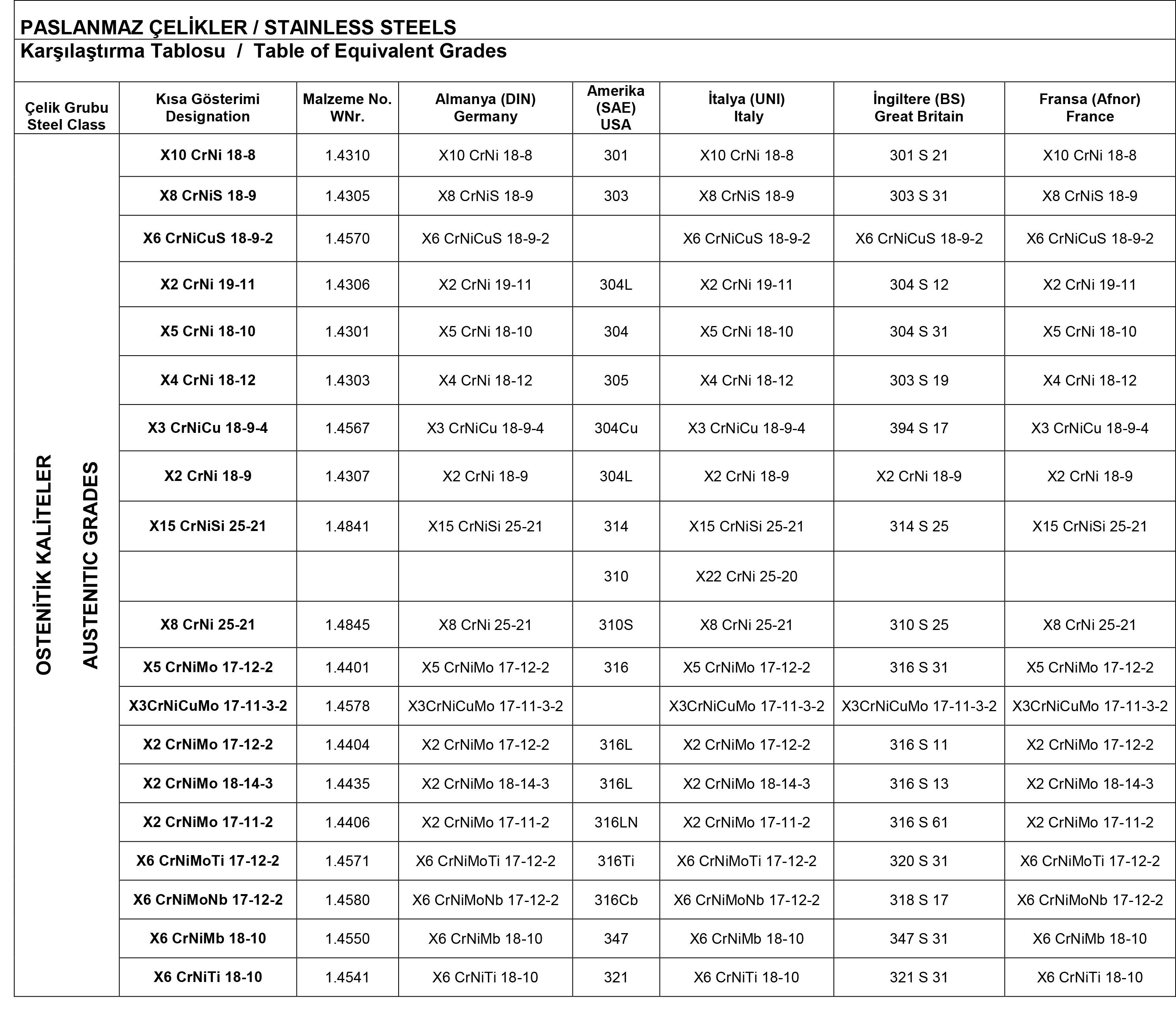

- Austenitic Stainless Steels

- Duplex Stainless Steels

- Precipitation Hardening Stainless Steels

Ferritic Stainless Steels

This group of stainless steels have min.12% Chromium (Cr) content. Ferritic Stainless Steels have certain useful corrosion properties, such as resistance to chloride stres-corrosion cracking, corrosion in oxidizing aqueous media, oxidation at high temperatures and pitting and crevice corrosion in chloride. Some alloying elements such as, Molybdenum improves pitting corrosion resistance while Silicon and Aluminum increase resistance to high temperature oxidation.

Atmospheric corrosion resistance of Ferritic Stainless Steels is excellent. These steels have good corrosion resistance in strongly oxidizing environments like nitric acid. In organic acids, all ferritic steels are superior to austenitic, but in reducing media general corrosion resistance of ferritic steels is worst than austenitic.

Martensitic Stainless Steels

This group of stainless steels contain 10,5-18,0 % Chromium (Cr), Carbon content of these steels is higher than ferritic stainless steels. Due to their higher Carbon (C) content they are hardenable by heat treatment and available at distorted body centered cubic structure after hardening. They have less corrosion resistance when compared to other groups. They are preferred if slight corrosion resistant properties are needed and generally they are used in fresh water. Martensitic Stainless Steels are ferromagnetic.

Austenitic Stainless Steels

This group of stainless steels are based of 18-30 % Chromium (Cr) and 8-20 % Nickel (Ni), due to their high Nickel (N) content and the characteristics of Nickel (Ni) which is stable at room temperature according to Ni-Fe phase diagram, they are not magnetic. This feature provides different application fields for austenitic steels. They have low carbon content and can not be hardened except deformation hardening. High Chromium (Cr) content allows excellent corrosion resistance an atmospheric conditions. But content of high Chromium (Cr) is not sufficient without Nickel (Ni) in superior oxidant media like hydrochloric acid or sulphuric acid. Resistance of these steels in other acids increase with the addition of Molybdenum (Mo) and Copper (Cu) and provides such extensive uses. Austenitic stainless steels are widely used in low and high temperature applications.

Duplex Stainless Steels

In cases of some applications, if high strenght is needed (especially high yield strenght) two phase (austenite+ferrite) duplex stainless steels can be used. The percentage of each phase depends on the chemical composition and heat treatment. Most duplex stainless steels are intended to contain equal amounts of ferrite and austenite phases in the annealed condition. Duplex stainless steels generally have similar corrosion resistance to austenitic alloys except they typically have beter stress corrosion cracking resistance. Duplex stainless steels have generally greater tensile and yield strenghts, but poorer toughness than austenitic stainless steels.

Precipitation Hardening Stainless Steels

They are Chromium (Cr)-Nickel (Ni) alloys. They are preferred in cases of high strenght applications beside corrosion resistance. Precipitation hardening stainless steels may be either austenitic or martensitic in the annealed condition. In most cases precipitation hardening stainless steels attain high strenght by precipitation hardening of the martensitic structure.